8 The soundboard

Nothing is more simple than the construction of an absolute fabulous sounding guitar! Just buy yourself a top of good-quality spruce, thin it to a thickness of "let's say" 0.5 to 1.0 mm (but still stiff enough). Put it on an existing or just made rigid guitar box. Put the strings on and you will not believe your ears! But within days you will not believe your eyes too! Because of the pulling force of the strings the top will curve soon - making the guitar false and unplayable. It is the well-known fact that in this case the constructional demands are in contradiction to the musical demands. Here it is impossible to prefer one principle above the other. We have to look for an optimum sound within the constraints prescribed by the laws of strength and playability.

These constraints cannot be described in terms of ultimate keeping qualities or in terms of detailed dimensions of plates, construction bars et cetera. On the one hand because of the many variables at stake. On the other hand because a specific strength can be achieved in several ways. For the soundboard you can improve the strength by the choice of the wood, by doming the top, by less thinning, by adding construction bars, by increasing the cross section of planned construction bars or by using the planned sound bars for construction purposes as well. In the description of how to make successive decisions in this context it is assumed that the construction reflects the idea of having a strong and rigid upper bout and a flexible lower bout. So the top of the lower bout forms the "effective soundboard" for almost all frequencies (say up to 1500Hz.) The waist bar, just under the sound hole, borders this soundboard. Sometimes this approach is referred as "the upper bout is structural and the lower bout is acoustical".

In going through the design process this black/white scheme should be used with care. Especially for the higher pitches the upper bout should be used to create places for characteristic oscillations. This "dual purpose" approach will be worked out in this paragraph. Apart from which approach you favor the best conditions for resonance are still given by a soundboard having a large number of natural vibrations over a range that includes all the harmonics produced by the strings.

At this moment it is good to keep in mind the difference between construction bars and sound bars. The function of construction bars is to strengthen the construction. To guarantee the guitar body can withstand foreseeable outer forces, but also to keep the soundboard in shape for many, many years. Sound bars have the function of leading the vibration of the bridge to all parts of the soundboard. A second function is to act as nodes in order to optimize the response to specific frequencies. So the sound bars, by their positions divide the soundboard into smaller parts that optimize higher characteristic oscillations. In other words: every frequency or partial should find its own piece of soundboard. Now for practical reasons it is desirable to take into account, that sound bars also have a function in strengthening the soundboard and doing so relieve the task of construction bars. The other way around construction bars may play a role (but a very minor one) in the acoustical tasks of the sound bars. In fact the combined task of construction and sound bars, together with the top in maintaining strength and optimizing acoustical functions is so complex that it is, at least in this time for mortal beings, impossible to come up with one unique mathematical solution for an optimal design.

The practical way is a "fix and improve" approach. That means: Find a solution in which the most important design principle (for that part of the guitar!) is optimized and then fine-tune that solution by taking other design principles into account.

Hereafter I will describe the design of the soundboard by taking the following steps:

Boundaries of the soundboard

The lower part of the soundboard is bordered on three sides by the outline of the lower bout and on the fourth side by the waist bar. This border can be more or less fixed. If the glue edges are rigid and the sidewalls are strong then the edge of the soundboard is clamped as firm as a rock and prevented from bowing there. On the other side if the sides are thinned and the glue edges tiny the top edges are allowed to bow. If you follow that approach the "effective" surface of the soundboard is enlarged. The effective width of the lower bout may be enlarged with 5 to 10 mm. That is not much but still worthwhile. It is hardly possible to use the same idea for the waist bar. The main function of that bar is to build a fixed construction point to connect both sides to each other and to strengthen the top, which is "damaged" by the sound hole.

Selection of the sound bars

As explained in chapter Acoustic principles the first function of the sound bars is to distribute the vibration of the bridge to different parts of the soundboard. This can be achieved in different ways, e.g. by a few sound bars or by many more flexible sound bars. The sound bars may consist out of one bar or may consist out several bars, which pass on the sound waves to each other. Now let's first discuss this last idea more in detail. From the discussion on the bridge remember that the wobbling, waggling movements of the bridge start the sound waves in the soundboard. It is possible to enhance the distribution of these waves with the aid of long sound bars that pass over and/or are connected to the bridge as e.g. in the case of the fan-wise design with 7 sound bars as commonly used by Torres. A second, different approach is to take the bridge as the starting point of the sound bar, using short, less flexible sound bars as e.g. in the Kasha-design. The design approach as described on this web site follows for a part the second approach. The reason for that choice is that the top plate should have the largest possible number of modes of oscillation and the idea of "mini soundboards" can be worked out more easily. Moreover the flexibility of the soundboard can be better adapted to the main wood resonances.

The second function of the sound bars is to divide the soundboard into "mini soundboards" suited to resonate at different frequencies. That is less obvious than it sounds. Also a top, without any construction or sound bar gives room to all kind of small waves or higher partials, with the restriction that the boundaries will act as nodes for those waves. In that way, adding "sub boundaries" may improve the acoustic properties of the top but only if these sub boundaries lead to suitable mini soundboards and does not stiffen the top in a negative way or at the wrong place.

The natural frequency of a plate is dependent of the elasticity (Young's modulus), the density and the dimensions of that plate:

Frequency ~ h/L2 * √E/d (see e.g. ref. 15)

With:

E = Young's modulus (constant for a given material)

d = density

h = plate thickness

L = width of the plate

So a plate with a width, that is 2 times smaller, will have a resonance frequency four times higher.

Now the main air resonance frequency of a classical guitar is very close to the lowest open string note (E). The lowest wood resonance peak (0.0) is higher, depends on all kind of material and construction details, but is in the order of ~200 Hz (see ref. 2). So this frequency is the fundamental frequency of a soundboard with an effective width (L) of about 36 cm.

Then the high pitch (~600 Hz) will ask for a resonance area of 36 x √200/600, so in the order of 20 cm. Another example is the area in the upper bout on both sides of the sound hole. These regions can be regarded as mini soundboards with an effective width of ~7 cm. The thickness of the top in that area may be 30% more than that of the lower bout. So the resonance frequency will be in the order of

200 x (36/7)2 * 1.33 ~ 7000 Hz.

Frequencies of that order are still important. Jansson (ref. 5) stated: Sounds filtered to give components only below 2000 Hz sound dull and hollow.

For that reason, in this first approach we will provide for several mini soundboards of that size and the way these mini soundboards are stirred.

This task looks more complex than it is, because even without sound bars specific locations of the top act as mini soundboards. Sound bars, well-positioned will enhance that effect. Creating a limited number of mini soundboards, clearly separated in their natural frequencies is generally sufficient to create a large number of possible places for the whole spectrum of different tones. This is caused by the variations in the dimensions of the different mini soundboards and by the broadening of the resonance peaks.

The soundboard is usually made out of two pieces of wood. The seam between these two top halves needs some reinforcement. Of course the grain of these strips has to run perpendicular to the grain in the top or back. This cross banding is applied to reduce the chance of a split along the center joint. If appropriate we will make use of that enforcement in such a way that it functions as a sound bar as well. The first task of the sound bars is to transmit the rocking movement of the bridge to those places of the soundboard that are meant to be the playing field for specific frequencies. In doing so an important question is whether you can better reach that goal with a one-piece sound bar or with a chained sound bar, that is a combination of several sound bars in succession. Take for instance the part of the top above the waist bar, or even above the sound hole. Those parts were predestined to enforce higher pitches (above ~7000 Hz). If we use a one-piece sound bar running from the bridge, passing underneath one or two arched crossbars up to those parts, we stiffen the top all along that road at cost of the basses. Making those sound bars flexible can hardly compensate that disadvantage and of course makes them less effective in connecting the bridge with the upper bout. In this case a chained bar, consisting of three smaller sound bars, one after the other, will have almost the same efficiency in stirring up the upper bout regions, but will be much better as far as the flexibility of the main soundboard concerns.

Positioning of the sound bars

At this moment we are ready for a first approach of the position of the sound bars. The first one is located in the middle along the seam. Two chained bars are heading for the openings in the waist bar. Two extra bars are located on the outside to reinforce the top, fulfilling the wish to homogenize the top and to provide some mini sound boards. The sound bars below the bridge are almost mirrored, but can be made less strong because the pulling forces of the strings will be transmitted mainly by the bars between the bridge and the waist bar and sides.

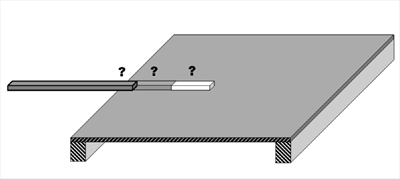

Now we have made a first sketch of the position of the sound bars, but we also have to decide on their length. Let's have a short discussion on that point. If you have a wooden membrane or (mini) sound board and you want to strike that board with a sound bar running from outside and connected to that soundboard for a certain length. At what point would you like to end that sound bar? Halfway the membrane? Run all over? Up to 1/3 or 1/4 of the diameter of the sound board? Common sense is enough to understand that the optimum is not "all over" because it would hamper the flexibility of the board. It should be somewhere between 1/4 and 1/2. Fortunately it is not difficult to set up a small experiment to find out, that the best choice is about 1/4. This conclusion will be used in the decision on the length of the sound bars and referred to as the "1/4 principle".

Image: The 1/4 principle

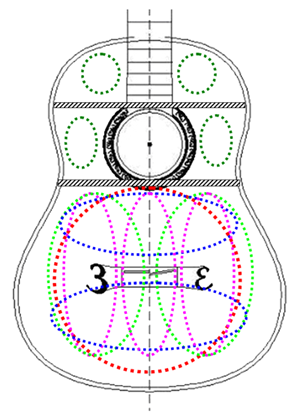

In chapter Acoustic principles I described some main wood modes of the top. Now take a drawing of the design of your guitar top, including the provisional place of the sound bars and delineate the modes, that play a decisive role, especially the fundamental modes like (0.0), (1.0), (0.1), (1.2) and (2.0) as indicated in image Main wood modes of the top.

Image: Main wood modes of the top

It is easy to see that some of these modes are almost free to move, where others will be hampered by the bridge or by sound bars. It is a challenge to find which sound bars will act as the main stirring mechanism of a particular mode or mini soundboard. But even more important, to what extent a sound bar will act as a node and seriously quench a specific mode. If the answer is clear you can decide on the length and position of that sound bar. The cross dipole (1.0) for instance may be hampered by the bridge, especially when the wings are long and stiff. Following the 1/4 principle you would end up with a bridge with a total length of ~ 9 cm. Applying the same reasoning for the tripole mode would favor a bridge with a length of about 18 cm. However for most frequencies a bridge without any wings may be the optimum (ref. 5). For that reason I prefer a bridge with a stiff middle part of 75 mm, a total length of 18 to 19 cm and wings that are adequately tapered towards the end.

See also the discussion on that subject in chapter The bridge.

Image: Sound bar location for the EB-guitars

Do not worry about the fact that this first approach is not the unique outcome of a mathematical procedure. There is not such an outcome. It is one of the unsolved mysteries where we have to look for a practical solution, based on experience as well. One well-known luthier, who has designed a lot of guitars conform the Kasha design, stated quite honestly: "I use a lot of tapping, flexing, listening and just general intuition and fun to get the top to where I want it." (ref. 9)

The "tap tone procedure"

Under "tap-tone-procedure" we understand construction adjustments to the thickness of the top or back and the associated construction and sound bars based on the tone (s) you can hear after tapping. It takes a little experience to find out how you can get the best (regarding volume and sound) tone out of a piece of wood by knocking on it. For a plate, half top, half back, top, back, side etc. in general you have to take firm hold of it between your thumb and forefinger. Then tap or knock forceful with thumb or finger of your other hand on the free hanging plate. Try out what the best place is for holding and tapping. Often you have to tap halfway the plate. Hold the plate close to your ear and listen carefully. In general you may hear one basic tone and sometimes several high tones (harmonics). If you remove material from the plate or from the bars the tap tone(s) will become lower. The goal of this procedure is to make the basic frequency louder, to improve the harmonics or to tune the tap tone of the back to that of the top during the construction.

It is important to realize that the tap tone of the top will change a lot after placing the sound bars and again after placing the bridge or after joining with the sides.

After the bars are glued to the top or the back there is another simple way to determine the natural frequency of the plate. If you have an electronic guitar tuner intended to attach to the head of a guitar, just clip it on the upper or waist transverse bar, knock and read the frequency from the dial plate.

Dome of the top

The top of your guitar may be flat or domed. The back is usually domed. To what extent the top or back should be arched is not the outcome of a mathematical procedure, but as usual, experience and application of physical principles will give us some guidelines on this issue. The advantage of a domed plate over a flat plate is an increased strength and resistance to deformations. The disadvantage is that the decreased flexibility will (frequency dependent) decrease the volume of specific pitches. This disadvantage holds especially for low frequencies like the fundamental mode (0.0). For high frequencies the volume will hardly be influenced by the curvature of the top. Waves with small wavelengths are not aware of the curvature of the plate so to speak. So if you want to favor the basses you have to limit the offset and choose for a dome that is just enough to prevent the top from indentation (dome ~ 2 mm). If you strive for more clarity in the high frequencies and a more even effect a dome of 3 to 5 mm is preferred.

Image: Work board to dome the plates

Experience has resulted in designs for classical guitars with an offset (maximum deviation from the flat plate) of 6 to 8 mm for the back and 2 to 3 mm for the top. The curve that the arched plate should follow is in most guitar construction books left to the reader. The usually given advice is to "slightly arch" the cross bars and arch the top or back by gluing it to these bars. Sometimes the arch is described as part of the contour of a circle or sphere with a specified radius. All these methods have the disadvantage to introduce unnatural strains in the top or back, that will result in energy losses in the vibrating plate.

Below you will find a short description of arching in a way the plates may choose their own "natural" curvature for a given maximum offset.

To dome the top (or back) the following steps are proposed (see image Work board to dome the plates):

- Prepare a work board (plywood) with the outer dimensions of your soundboard

- Heighten the outer contour with the aid of cork up to ~8 mm

- Position the top on the work board and press the top down to the chosen offset with a stamp; this stamp should be positioned at the center of the lower bout (equals the middle of the planned bridge) or better ~30 mm towards the fingerboard

- Measure the course of the offset all over the plate and make a map of it (compliance map)

- Remove the plate from the work board and fill the work plate with a cork plate (thickness again ~8 mm)

- Sand the cork plate so it duplicates the offset map

- Place the soundboard on the work board; put on the stamp and move it to the maximum possible depth (so the offset all over the soundboard reflects the compliance map)

- Place all important construction and sound bars at their planned positions and plane or sand them to the curve as given by the impressed soundboard

- Glue on all construction and sound bars

- Wait at least one week before you remove the soundboard from the work board

Dependent on the pattern of the construction and sound bars the offset of the plate will decrease as soon it is taken from the work board. For the EB-guitars, with their relatively flexible tops the offset decreases from 7 to 4 mm. So finally, dependent on the flexibility of your top, for a dome of 2 mm you have to choose an offset of your work board of 3 to 4 mm. For a dome of the back of 5 mm you have to take, again dependent on the flexibility of the board, an offset of 7 to 9 mm.

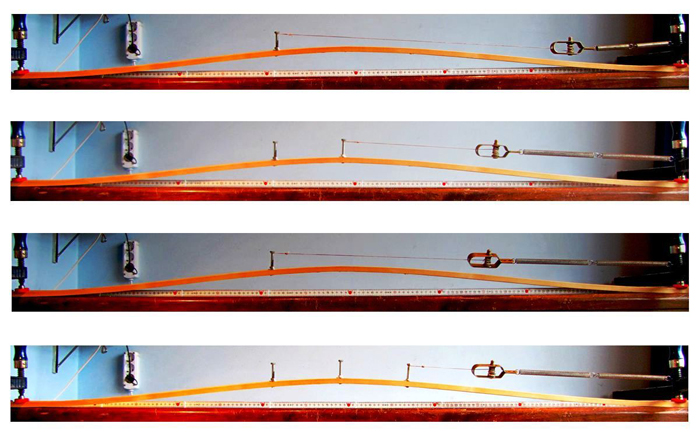

Lastly a remark on the place you want to position the maximum deviation. In the step-by-step approach before the center of the bridge was indicated as such. Clearly because the vibrations in the soundboard are triggered from that point. A small correction to that choice is worthwhile. In the beginning of this chapter the problem of deformation of the soundboard due to the pulling forces of the strings was mentioned. The chance that this deformation will take place can be decreased by moving the top of the dome towards the neck. A simple test as shown in image Test on the position of the top of the dome can give us an indication of this effect. During this test a domed spruce board was bended pulling at locations in front of, at and behind the top of the dome. Measuring all deviations as a function of the point of application gives an indication of the benefit of moving the top of the dome upwards to the neck. Taking into account all differences between the parameters in the test and a real classical guitar top it seems that placing the top of the dome ~5 cm in the direction of the neck will decrease the impression caused by the strings with a factor of 5. On the whole my advice is to position the stamp as described before about 3 cm to the right (towards the sound hole) from the middle of the bridge.

Image: Test on the position of the top of the dome

Thickness of the top

The thickness of tops of classical guitars varies a lot. First of all it depends on the choice of wood. Red cedar asks for a thickness of 1.5 to 2.0 mm. Spruce is often the first choice because of its acoustic properties and because it can be thinned to 1.5 mm and, if adequately braced, still keeps enough stiffness and strength.

The strength of the top is a combination of top wood, construction bars and sound bars, but far from just "adding" those three. In the case of construction bars, glued underneath the top, with the grain perpendicular to the grain of the top wood (cross bars), extra protection to cracks along the longitudinal axis is provided. The same holds for sound bars, that runs more or less perpendicular to the top wood fibers. Construction bars parallel to the plate fibers is another story. If you may choose between a normal plate with an extra bar or the same plate locally extra thick (resulting in the same overall strength) you should choose for the last option. Fortunately such a choice has hardly to be made. Only in the upper part of the guitar body it is interesting to have a relatively thick top.

Now let's have some thoughts on variation of the top blade thickness. Imagine that you start with a thickness all over the top of 2 mm. Thinking of the main wave resonances it looks favorable to make the top flexible at places where it has to "flex" the most. From that viewpoint the top should be thinned as follows:

- Around the contour and in the vicinity of the waist bar (wave modes (0.0), (1.0) and (0.1))

- Along the midline/seam (wave modes (1.0), (1.1) and (1.2))

- Along the bridge (wave modes (0.1), (0.2), (1.1) and (1.2))

In view of the strength of the top around the sound hole an extra thickness of 0.2 to 0.4 mm may be an alternative to the usual construction in the form of a square or circle strengthening. Taking into account the wish to have extra support perpendicular to the grain of the top you should look for strengthening of the sound hole region especially in that direction and to choose a thickness in that region that is enough to compensate for the loss of strength. These ideas are in line with having a local mini soundboard in that region with a resonance frequency of ~7000 Hz.

Final construction

Now your first concept of the top is ready, it is time for "fine tuning". There is still some elbowroom. Strength can be obtained by more thickness of the top, higher construction- or sound bars or less spaced sound bars. To gain insight in these possibilities it is good to make some simple comparisons.

Take for example the situation of sound bars of the same material as the top, with a height of 3 times the top thickness, running parallel to the grain of the top and spaced 20 mm of each other. In that case the resistance against bowing parallel to the grain is equally shared between the top itself and the sound bars. Decreasing the top thickness with 10% from 2 mm to 1.8 mm can be compensated by increasing the height of the sound bars from 6 to about 7 mm. In the situation that the sound bars as described in this example make an angle of 45° or 90° with the grain direction of the top the necessary increase of height is of course even less, because the strength of the top is less perpendicular to the grain. Variations like these have to be within certain limits. As you know the positions of the sound bars were already fixed. The thickness of the top should be chosen within the lines described in the foregoing paragraph. Variations in thickness should be gradual. Variations in thickness means cutting through the wood fibers and that is something you want to avoid if possible.

Going through examples and simple calculations like these you will find that the changes within these constraints are small. Important is that the choice between stronger bars or a thicker top is dependent on the exact location at the top you talk about. In regions of mini soundboards meant to resonate at a high pitch you can afford to allow a thicker top and a corresponding decrease in bar enforcement.