9 The back

As in the case of the soundboard let's first think about the acoustical function of the back. In chapter The bridge I argued that the whole guitar box should be as rigid as can be with an exception for the top and the back in its function to support the main air modes. So we have to know which parts of the back contribute to those modes. In this respect it is sufficient to distinct just two parts: the upper and the lower bout.

From experiments on "standard backs", e.g. of normal size and usual bars we can conclude that it is only the lower part of the back that moves and contributes to the air modes (0.0), (0.1) and (0.2). The main reason of course is that the upper part of the back is stiffened anyway by the inevitable connection with foot and heel. Now, as in other construction parts of the guitar, it is of no use to have energy absorption in parts with a minor or no contribution to the sound production. Therefore the best solution is found in a back, which is rigid in the upper part and is flexible in the lower part. As a start, depending on the wood, you should think of a thickness of 2.5 mm max for the upper bout and 2.0 mm max for the lower bout.

This starting point should be worked out in the same way as we did for the soundboard.

The lower part of the back is bordered by a cross bar, which location is chosen in the same way as the waist bar of the top. It will be positioned right under the waist bar. As far as the flexibility of the back is concerned, especially the (0.0) and (0.1) modes we like to back up. Do not think in terms of sound bars that distribute sound waves in the wooden back or should divide the back into "mini backs". The task of the back is only to reinforce the guitar box and to show flexibility needed for optimization of the (0.0) and (0.1) modes. That goal has to be reached by a combination of wood thickness and construction bars. The argument to use construction bars as well is based upon the fact that the strength of a piece of wood is much (order of ten times) higher in the grain direction than perpendicular to that direction. The different viewpoints, mentioned above, lead to a strengthening of the back by a star pattern with its center in the middle of the lower part of the back. It looks a little bit like the X-pattern of the steel string guitars but with the "X" centered in the lower back. What we strive for is a strengthening that is rather homogeneously divided and therefore we have to use more radians and have to decrease the radians in the center. If we want to have a symmetric pattern (and the air modes are symmetric) we end up with a star with 8 radians. It will be clear that such a pattern will stiffen the center of the belly unnecessary and therefore we will let the radian's end at a certain distance from the center and from the boundary. This "✴" pattern is also quite suitable for fixating the tail block to the neck.

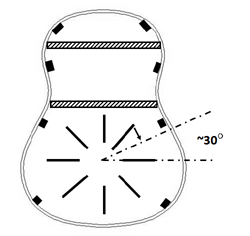

Image: Bar pattern for the back

A second modification of the star pattern is based on the view that the strengthening should be focused in the direction perpendicular to the grain of the back. So the radians crossing the grains should be located closer to each other. I don't think, if possible at all, that there is an algorithm available that gives you an exact solution for the position of the radians in this way. There are too many variables involved. But the optimum solution should show the appearance shown in image Bar pattern for the back.

In that pattern all radians end at a distance of the center of 5 cm from the center and 4 cm from the boundary. The sidewards pointing radians make an angle of ~30° with the cross bar. For arching the back see the discussion in chapter The soundboard.